Back to the 70's - Mitre Cut Sails

Back in the seventies it wasn't just all about bushy hair and bad fashion. Actually it was! But in the sailmaking world, it was the realm of the mitre cut. When I began sailmaking in the late 70's at Brooke Sails, under the tutelage of Noel Brooke, every headsail we made was a mitre cut sail. The reason was pretty simple, the Dacron sailcloth we used was pretty crappy compared to todays woven cloths and Carbon was something that was left over on the grill after a BBQ! Sail Design was a lot harder back then as the Sail-maker had to think of not only shape but cloth stretch as well. The cloth was very spongy and stretched a lot, particularly in the warp direction along the roll and even more so on the bias. It was marginally more stable on the Fill or Weft direction. I can remember the late Ben Lexcen (or Bob Miller as he was then) telling me that they had to cut their 12 metre class mains 9" (230mm) short on the leech to allow for stretch as the mainsail was sheeted on. The mitre cut was the best solution as it lined up the Fill direction of the cloth with the higher load areas along the leech and foot of the sail.

As cloth improved and became more stable, the crosscut became more the fashion and lately even radial cut woven sails are popping up. Although be wary if getting a Radial cut Dacron Sail, make sure it is specifically engineered for Radial Construction, I have seen some horror stories!

But every now and then along comes a job that requires a more traditional approach . We were recently commissioned to build a Yankee Furling Jib for a Roberts 43 Ketch.

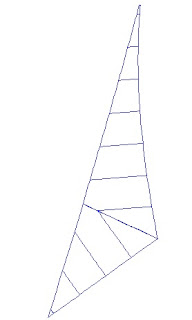

As you can see by the design in the top right hand corner. It is a very tall thin sail with a very high clew, this is for sheeting well aft and to make tacking easier. The best solution was to roll out the old Mitre cut as the best option for this configuration of sail. A crosscut sail was not an option for an effective sail. A traditional configuration requires a traditional solution. So back to the sewing machine to continue on with the sail (some things haven't changed since the 70's)>

As you can see by the design in the top right hand corner. It is a very tall thin sail with a very high clew, this is for sheeting well aft and to make tacking easier. The best solution was to roll out the old Mitre cut as the best option for this configuration of sail. A crosscut sail was not an option for an effective sail. A traditional configuration requires a traditional solution. So back to the sewing machine to continue on with the sail (some things haven't changed since the 70's)>

As cloth improved and became more stable, the crosscut became more the fashion and lately even radial cut woven sails are popping up. Although be wary if getting a Radial cut Dacron Sail, make sure it is specifically engineered for Radial Construction, I have seen some horror stories!

But every now and then along comes a job that requires a more traditional approach . We were recently commissioned to build a Yankee Furling Jib for a Roberts 43 Ketch.

As you can see by the design in the top right hand corner. It is a very tall thin sail with a very high clew, this is for sheeting well aft and to make tacking easier. The best solution was to roll out the old Mitre cut as the best option for this configuration of sail. A crosscut sail was not an option for an effective sail. A traditional configuration requires a traditional solution. So back to the sewing machine to continue on with the sail (some things haven't changed since the 70's)>

As you can see by the design in the top right hand corner. It is a very tall thin sail with a very high clew, this is for sheeting well aft and to make tacking easier. The best solution was to roll out the old Mitre cut as the best option for this configuration of sail. A crosscut sail was not an option for an effective sail. A traditional configuration requires a traditional solution. So back to the sewing machine to continue on with the sail (some things haven't changed since the 70's)>

Comments

Post a Comment